使用用途与简洁/Brief Introduction:

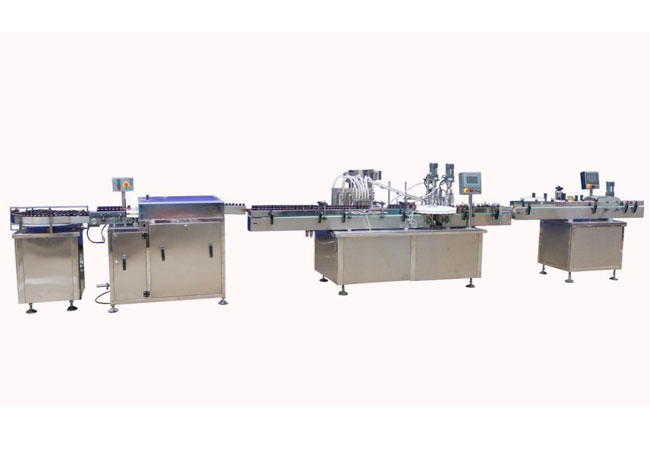

本产出线适30ML大于内服液的装灌产出,由供瓶机、辊子洗瓶机、直线方程式装灌轧(旋)盖机、旋转式标贴纸机等设施成分,可全手动顺利完成理瓶、洗瓶、装灌、上盖、旋(轧)盖、标贴纸等工步。一般广泛用于医药、商品、纸业的的各项药液物料清单的装灌三级联动产出。本产出线彻底合适GMP想要。This production line is suitable for more than 30 ml of oral liquid filling production, by for bottle filling machine, roller bottle washing machine, straight-line rolling (spin) cover machine, vertical labeling machine and other equipment, can finish automatically unscramble bottle, bottle washing, filling and cover, cover and label (pad). Mainly used in pharmaceutical, food, chemical industry production of all kinds of liquid filling material of the linkage of. This production line in full compliance with GMP requirements.

共同点 /Characteristic:

◆表面原料为304304不绣钢,分装部分组采316L304不绣钢,按照GMP规范起来。Outer material is 304 stainless steel,and the material of filling part is 316L stainless steel, it complies with GMP regulation ◆可适于多规格参数生孩子。can be situable for several bottle specs.◆正常运行平稳,噪音分贝小,装罐明确 。Stable running,low noise,precise filling.◆破瓶率低,原料适合率高,用电量少。low bottle breakage ratio,high qualified product ratio,low energy consumption.◆成条生产方式线可单机版设定和加盟设定。The whole line can single machine control or interlock control.高技术技术参数表/Main Technical Parameters:

用于规格尺寸Filling Volume | 30-150ML |

灌装生产线头数Productivity | 低速度4头 &nb﷽sp; 速度8头 4 at low speed &nbs🍎p; high speed 8 |

生产的力量 | 中速30-50瓶/分 高速收费站70-100瓶/分 30-50bottles/min 70-100bottles/min |

包装可靠性强,精密度Filling Precision | ≤±1% |

旋盖率Capping Rate | ≥99% |

供电Power Supply | 220V/50Hz |

工作电压Power Supply | 2.5kw |

生产的线总长Dimension | 7500*1000*1700MM |

-

18217001818

18217001818

-

shnalong@aliyun.com

shnalong@aliyun.com

-

武汉纳庆机械机械机械有限总部英文总部

武汉纳庆机械机械机械有限总部英文总部

中文

中文  English

English